- Home

- Customer Examples

- Stainless Steel Equal & Reducing Tees for PDH Project

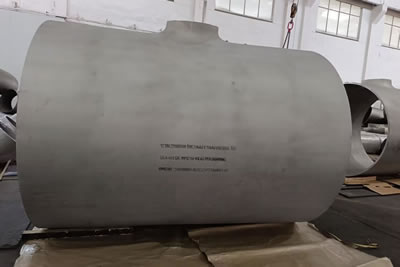

Stainless Steel Equal & Reducing Tees for PDH Project

The large-size, custom-made seamless extruded equal & reducing tees were manufactured according to tailored drawings and specific technical requirements. All products were produced following the confirmed ITP and inspected by the appointed TPI. Made from SS321H, the tees are available with sizes of DN2100 and DN2250, with wall thicknesses of 22mm, 26mm, 28mm, and 45mm, and a maximum raw material plate thickness of up to 52 mm.

For these large tees, the branch outlets were seamlessly extruded exactly as required by the EPC for the Propane Dehydrogenation project. Clients consider these fittings outstanding: they are unique, high-quality, and fully meet the strict project standards.